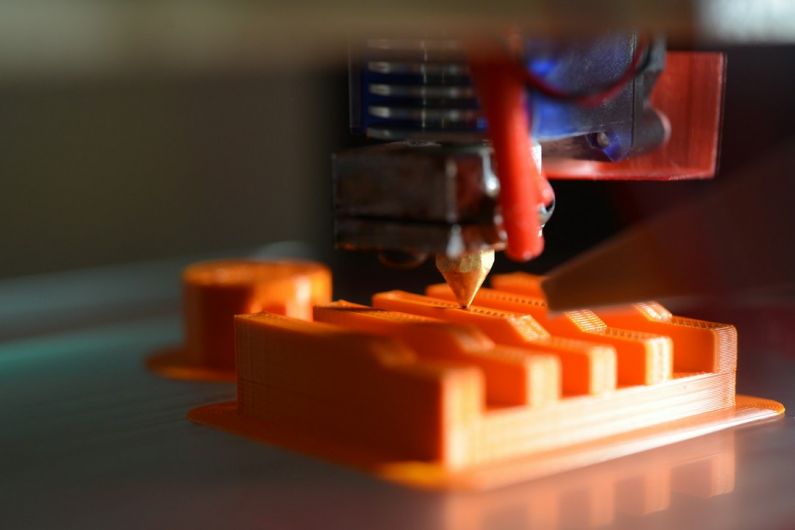

Manufacturing has come a long way since the advent of the Industrial Revolution. From mass production to automation, technology has played a pivotal role in shaping the manufacturing industry. One of the latest technological advancements that is set to revolutionize manufacturing is 3D printing. Also known as additive manufacturing, 3D printing offers a range of benefits that have the potential to transform the way products are made. In this article, we will explore how 3D printing can revolutionize manufacturing.

1. Increased Design Flexibility

Traditional manufacturing methods often have limitations when it comes to design. Complex shapes and intricate details can be challenging to produce using conventional manufacturing techniques. However, 3D printing eliminates these limitations by enabling the creation of intricate designs with ease. With 3D printing, designers have the freedom to experiment with shapes and structures that were previously unimaginable. This increased design flexibility opens up a whole new world of possibilities for manufacturers, allowing them to create products that are not only functional but also visually appealing.

2. Faster Prototyping

Prototyping is an essential part of the manufacturing process. It allows manufacturers to test and refine their designs before mass production. However, traditional prototyping methods can be time-consuming and costly. With 3D printing, prototyping becomes faster and more cost-effective. Manufacturers can quickly create prototypes by simply sending a digital file to a 3D printer. This eliminates the need for complex tooling and reduces the time it takes to bring a product from concept to market.

3. Customization and Personalization

In today’s consumer-driven market, customization and personalization are key factors that drive customer satisfaction. 3D printing enables manufacturers to offer customized products at a mass production scale. By leveraging the power of 3D printing, manufacturers can easily tailor products to meet the specific needs and preferences of individual customers. This level of customization not only enhances customer satisfaction but also opens up new business opportunities for manufacturers.

4. Reduced Waste and Cost

Traditional manufacturing methods often result in significant material waste. This not only has an environmental impact but also adds to the cost of production. 3D printing, on the other hand, is an additive process that only uses the material required to create the final product. This significantly reduces material waste and lowers production costs. Additionally, 3D printing allows for on-demand manufacturing, eliminating the need for excess inventory and storage costs.

5. Supply Chain Optimization

The traditional manufacturing supply chain is often complex and involves multiple stakeholders and processes. This can lead to delays, inefficiencies, and increased costs. 3D printing has the potential to simplify and optimize the manufacturing supply chain. With 3D printing, manufacturers can produce goods closer to the point of consumption, reducing transportation and logistics costs. Furthermore, it enables the decentralization of production, allowing manufacturers to respond quickly to changing market demands.

In conclusion,

The emergence of 3D printing has the potential to revolutionize the manufacturing industry in numerous ways. From increased design flexibility to faster prototyping and customization, 3D printing offers a range of benefits that can transform the way products are made. Moreover, it reduces waste, lowers costs, and optimizes the manufacturing supply chain. As technology continues to advance, it is likely that 3D printing will become an integral part of the manufacturing process, shaping the future of the industry.